WITH A GLIDER THROUGH THE WORLD!

Sometimes we at sigma3D get unusual customer requests. This is also the case here:

Our customer is the owner of a glider and wishes to turn it into a motorized glider. In order to realize this, the glider needs what distinguishes it from a motorized glider, an engine.

CUSTOMER REQUIREMENT:

The engine should be installed in the fuselage. A flap is to be installed in the fuselage shell so that it can be accessed easily in the future.

One of the customer's problems was that no data was available from his glider to plan the installation exactly. The requirement for sigma3D was to create a NURBS model. Everything should be reproduced in detail, i.e. the actual state with every dent and traces of use. This was necessary to mount the flap accordingly

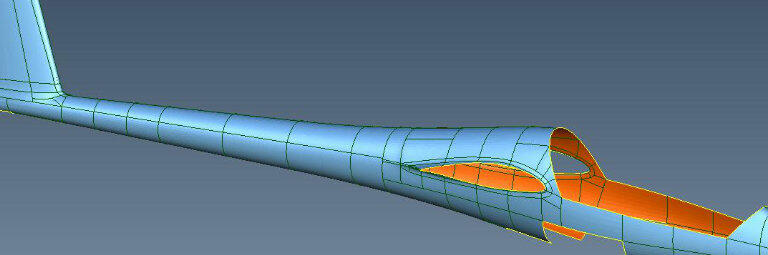

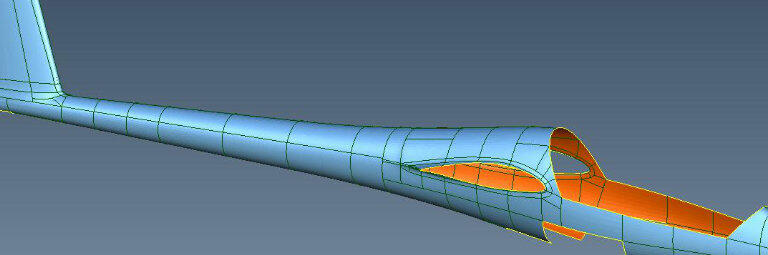

No fully editable (parametric) CAD model was required for the planning. Instead, a more cost-effective variant for the customer was chosen with the construction of a surface model using free-form surfaces. This approach is best suited for surfaces such as car bodies, aircraft fuselages, consumer goods with a complex shape. The CAD models created in this way are referred to as NURBS-generated CAD data.

Measuring task:

The glider was measured with a Faro laser tracker and the corresponding scan arm. The resulting data can be recognized as a point cloud.

In the first step, a polygonal model was generated and optimized from the 3D point cloud. For this purpose all points are meshed with their neighboring points. The result are thousands of triangles (polygons) which describe the surface of the scanned object.

Next, a curve network is built over the scanned object using special CAD software. Depending on the scan objects, several hours of optimization of the curve network are required before the final free-form surfaces can be calculated.

RESULT:

The result is a NURBS-generated surface model. The generated surfaces lies on the scan data with a high degree of accuracy and thus precisely reflect the real object. The CAD models can be scaled, trimmed and merged, but it is not possible to thicken them or edit partial areas without restrictions. This is due to a fundamentally different mathematical approach compared to the parametric CAD model.

For our customer we have created what he wanted. By reverse engineering the glider, the flap could be installed at the right place and the engine could be let in.

Our customer is now flying his circles with his motorized glider!

If you have any questions in this regard, please do not hesitate to contact us!